In a dilute phase conveying system, the product is transported by lift, or suspension, of the individual particles in the air stream. As the velocity is subsequently reduced, the larger particles cannot sustain this lift and they begin to fall from suspension to the bottom of the pipe. The technical term used in the industry that describes the velocity at which particles fall from suspension from the air stream is "saltation velocity".

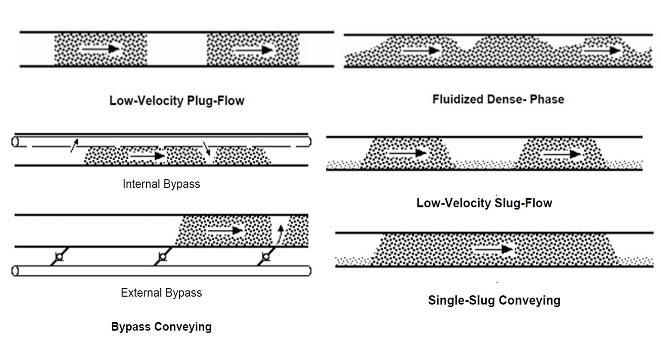

The main principle of a dense phase conveying system is to slow down the velocity of the product in the pipe to a point that is below the speed at which the product breaks or degrades. At low velocities, the product lies for periods of time in the bottom of a horizontal line and it is blown under pressure to the discharge point in slugs or plugs.

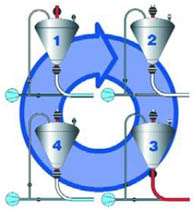

The dense phase pneumatic conveying systems uses low volume, medium pressure air stream and relies on a continuously expanding volume of air pushing cohesive slugs of material along the pipe. This system uses a transfer vessel/pump tank to feed the material into the conveying line. It is a batch system with plugs of material separated by cushions of air.